|

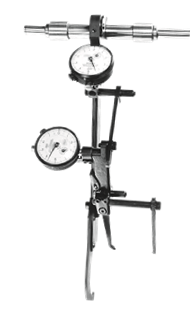

SINGLE DIAMETER CALIPER

Great for extended production runs or repeating jobs. Each caliper is custom made, lapped to exact size, and marked. Available from .187”-20” (4.75mm-508mm).

|

|

ADJUSTABLE CALIPER

Adjustable calipers can be set to a new size with a hex wrench. Each has a graduated scale for easy setting. Round (disc) carbide contacts are standard. 1-3” and 3-5” calipers are available with flat contacts especially for crankshaft grinding. Flat contacts are available for other caliper sizes. as a custom option.

|

|

SPLINE CALIPER

Custom made and lapped for gaging diameters with interruptions such as splines, keyways and flats. Available from .375”-8” (10-200mm)

|

|

SINGLE DIAMETER CALIPER |

|

SPLINE CALIPER |

|

LARGE CALIPER |

|

Customize your ARNOLD GAUGE System! |

|

More Information... |

|

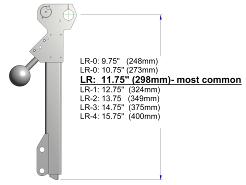

Our standard “LR” ARNOLD Gage frame (11.75” long) is perfect for most grinding jobs.

Use this table to select the proper Gage frame for your application:

|

|

TRUNNION STORAGE RACK |

|

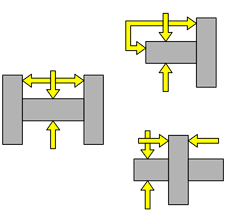

MODEL LRWF (for diameters and widths) |

|

2. CHOOSE AN INDICATOR... |

|

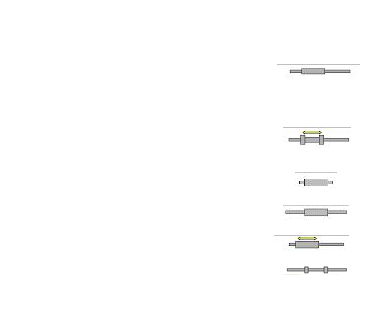

ARNOLD dial indicators include a special dovetail back for secure mounting to the gage frame. The following models are available:

|

|

3. CHOOSE A CALIPER... |

|

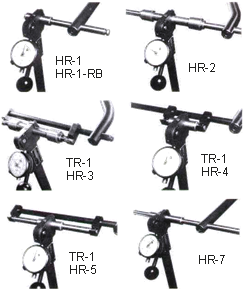

HUB STYLE |

Description |

When to use |

|

|

HR-1 |

Most common Laterally fixed |

Most common |

|

|

HR-1-RB |

Includes roller bearing |

Sensitive diameter gaging |

|

|

HR-2 |

Includes floating ball bearing for lateral sensitivity |

WF and LRWF Gages |

|

|

HR-3 |

Trunnion floating ball bearing for lateral sensitivity |

WF, LRWF, TR-1 |

|

|

HR-4 |

Short Trunnion Laterally fixed |

TR-1 in limited space |

|

|

HR-5 |

Long Trunnion Laterally fixed |

HR-3 and TR-1 |

|

|

HR-7 |

Sliding Hub with extended lateral float |

CRANKSHAFT and CAMSHAFT grinding |

|

|

TR-1 |

Trunnion Hook Rod |

HR-3, HR-4, HR-5 |

|

|

For ALL of these hubs, we recommend a DG-4 Dog Assembly to support your ARNOLD GAUGE when retracted |

|||

|

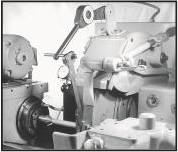

ARNOLD GAUGE mountings assure sensitive gage support while gaging, and lift the gage out of the way while swapping workpieces.

Model JR mountings include hydraulic motion control for smooth, shock-free operation.

|

|

All mountings attach to your grinder (wheel guard, headstock, tailstock) with a single 1/2” Bolt. Three set screws allow you to accurately align the gage to your workpiece. |

|

1. CHOOSE A GAGE FRAME... |

|

4. CHOOSE A GAGE HUB... |

|

MOUNTING OPTIONS… An ARNOLD GAUGE can be mounted in a variety of ways... |

|

5. CHOOSE A MOUNTING ARM... |

|

Mounted to Top of Wheel Cover (uses a custom bracket) |

|

Mounted to Right Side of Wheel Cover |

|

Mounted to Rear of Headstock |

|

Mounted to Front of Headstock (uses a custom bracket) |

|

TRUNNION STORAGE RACK

The model TRS Trunnion Storage Rack mounts near the operator and holds up to 4 grinding gages equipped with trunnion style hub assemblies (HR-3, HR-4, HR-5). The operator simply takes a gage and snaps it into place. This saves time when grinding parts with 2 or more diameters to gage. |

|

The Arnold model LRWF provides a continuous reading of both width and diameter during the grinding cycle.

This flexible, modular system allows several different configurations: |

|

ADJUSTABLE CALIPER |

|

6. CHOOSE A MOUNTING |

|

Size (inches) |

Size (mm) |

Notes |

|

.1875-1.5” |

6-40 |

|

|

1-3” |

25-75 |

Available with flat contacts for crankshaft grinding |

|

3-5” |

75-125 |

|

|

5-8” |

125-200 |

|

|

8-12” |

200-300 |

|

|

12”+ Up to 24” |

305+ Up to 610mm |

Each has 1” (25mm) of range |

|

LR (Standard) |

11.75” (298mm) |

|

LR-0 |

10.75” (273mm) |

|

LR-3 |

14.75” (375mm) |

|

Frame # |

LENGTH |

Notes |

|

LR (standard) |

11.75” (298mm) |

Most common |

|

LR-0 |

10.75” (273mm) |

Use if your grinding wheel is 12” (305mm) or smaller |

|

LR-3 |

14.75” (375mm) |

Use for large crankshaft grinding |

|

Please contact us for other lengths |

||

|

Indicator # |

Resolution |

Range |

Features |

|

194028 |

.0005” |

.20” |

Rev Counter |

|

194002 |

.0001” |

.025” |

Rev Counter |

|

194003 |

.0001” |

.20” |

Rev Counter |

|

193703 |

.00005” |

.015” |

Rev Counter |

|

194702 |

0.01mm |

2.5mm |

Rev Counter |

|

194701 |

0.002mm |

0.5mm |

Rev Counter |

|

Digital Indicator available upon request |

|||

|

Arm Length |

Use if your caliper size is... |

Notes |

|

8” |

Under 5” |

Most common |

|

10” |

5-8” |

|

|

12” |

8-12” |

Use if required by mounting distance |

|

14” |

|

Use if required by mounting distance |

|

16” |

|

Use if required by mounting distance |

|

Offset mounting arms available |

||

|

Mounting Style |

When to use |

|

JR |

Most common |

|

JR: Heavy Duty |

With a 14” or 16” mounting arm, or caliper larger than 12” |

|

JR: Reverse |

When mounting on the left side of grinder |

|

BB |

When using multiple gages in tight spaces |